Your contact options

Johannes Hübner Giessen

- 0123 4567 89

- 0123 4567 89

- info@huebner-giessen.com

Rotary encoders from Johannes Hübner Giessen are available in various sizes and with different mechanical interfaces. Extensive, suitable accessories are available for each mounting. And should the situation on site require it, the engineering support will assist in finding and implementing a customized mounting solution. On request, on-site measurement and installation are also possible.

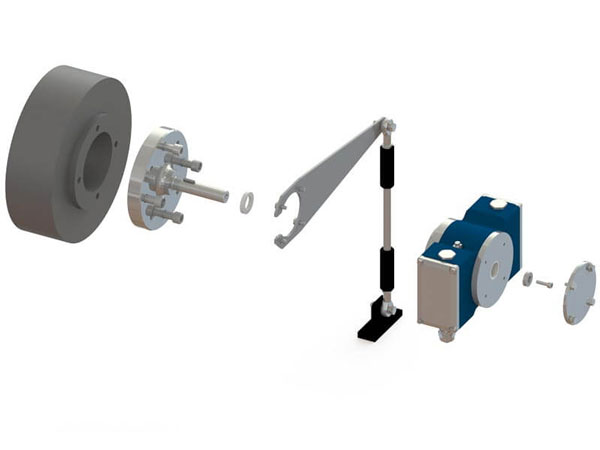

Both optical encoders and magnetic encoders are suitable for direct mounting on hollow shafts.

Depending on the application shaft, the customized hollow shaft mounting is realized with individually designed flange or screw-in adapter shafts as well as suitable torque brackets.

Optionally, there are solutions for hollow shaft mounting in insulated design against unwanted shaft currents. Safety-certified mounting with fatigue resistant safety components and fault exclusion according to DIN EN ISO 13849-2 (PL e) is also possible.

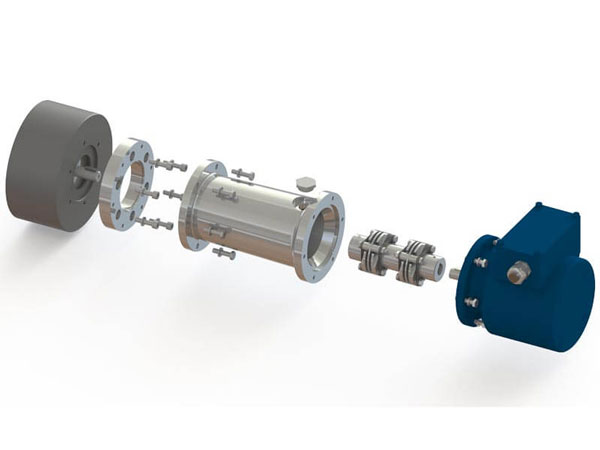

For solid shaft mounting with flange, the rotary encoder is mounted via a coupling with a customized intermediate flange.

Optional solutions are available for solid shaft mounting with flange in insulated design against unwanted shaft currents. Safety-certified mounting with fatigue resistant safety components and fault exclusion according to DIN EN ISO 13849-2 (PL e) is also possible.

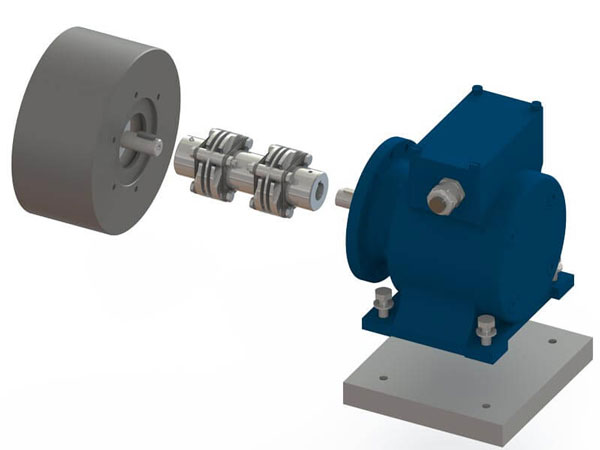

For solid shaft mounting with foot, the rotary encoder is attached to the motor shaft using a suitable coupling. In addition, the encoder is screwed to a fixed base plate, which can be customized if required.

Optional solutions are available for solid shaft mounting with foot in insulated design against unwanted shaft currents. In addition, safety-certified mounting with fatigue resistant safety components and fault exclusion in accordance with DIN EN ISO 13849-2 (PL e) is possible.

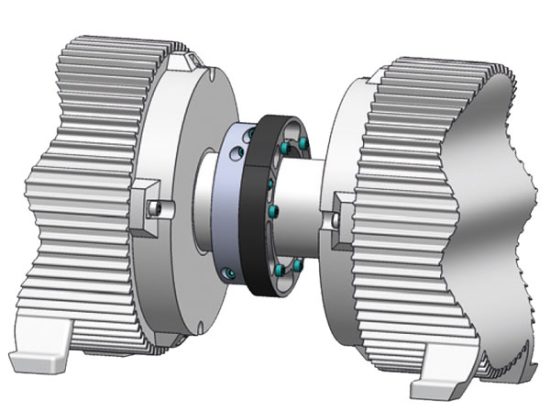

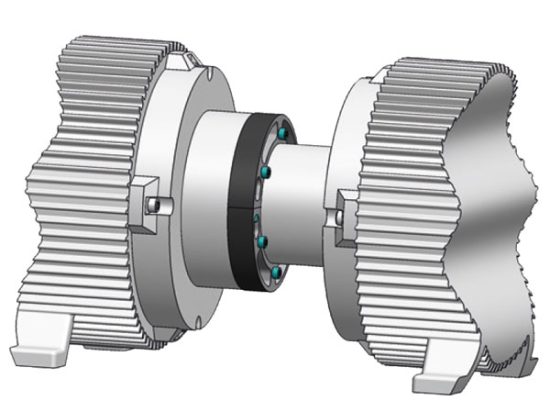

For mounting situations where no free shaft end is available, incremental or absolute magnetic encoders are the optimal solution. With a split pulse wheel, they can be mounted easily and without time-consuming assembly and disassembly work, making them ideal for retrofits and modernizations where the encoder has to be integrated into an existing system.

The pulse wheel is screwed either to the shaft shoulder or to a clamped centering ring. The scanning head is fixed to a customer-specific mounting device.

We look forward to your challenges.